The optimization of energy resource structure has taken place in the world, and environment protection is attracting increasingly more attention. LNG (liquefied natural gas) is regard as the cleanest energy worldwide. More and more countries tend to use LNG with respect to its cleanness.

Our company began to develop LNG purification and liquefaction plant as early as in 1980s. By now, we have provided about 30 sets of LNG separation plants. The technique includes expander process, MRC mixed cold process, etc. We also made the first set of 100% skid-mounted LNG plant (50000Nm3/day) in China, which was installed in Inner Mongolia in 2015.

Features of our skid-mounted LNG plants

1. Highly compact skid-mounted structure: total 3 parts including

1) Metering, pressure control & purification system package;

2) Liquefaction system;

3) Public utility and accessories. After all packages are transported to the site, the client only needs to connect the flanges, pipelines, etc. Once the LNG plants set on the foundation skid, which greatly reduces workload on site.

2. Highly integration of prevailing internet of objects technology (IOT): DCS self-control system;

3. Short time of construction and high efficiency: 3-6 months for manufacturing and only 15 days for installation and commissioning.

4. The LNG plants are featured by small land occupation, environmental friendly and low energy consumption. The whole LNG plant can be installed on a field of 60*60m, the main equipment/device is only about 16.5*16.5m; during very short period, the whole plant can be easily moved from one to another;

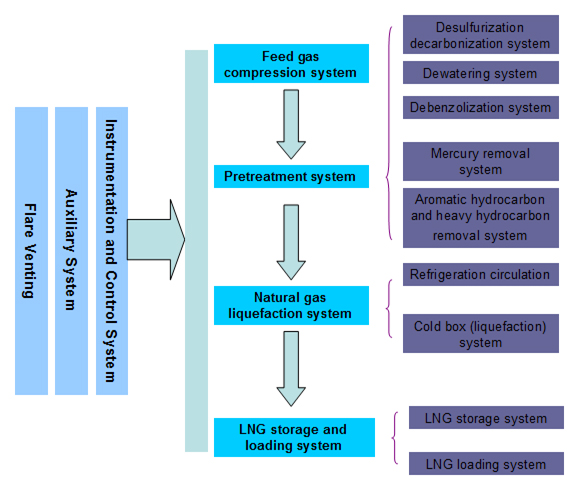

Natural gas pre-treatment and purification system including:

1. Desulphurization decarbonization system

Process: (MDEA+MEA) mixed amine method

(MDEA+ activator) MDEA method

Software: AMSIM which is recognized by Chinese authorities

Results: CO2<50ppm, H2S<4ppm

2. Dehydrating system

Dehydration by using 4A molecular sieve

Process by using three towers (or two towers): less regenerative gas is needed; more stable in operation

Molecular sieve dryer: it is designed in accordance with GB150 and tested by fatigue analysis

3. Mercury removal system: 10ng/nm3

The sulfur-loaded activated carbon is used to adsorb mercury, which can be used for 3-5 years. It is one tower or two towers, no need for regeneration. A filter is set behind the mercury removal system.

4. Aromatic hydrocarbon and heavy hydrocarbon removal system

From heavy hydrocarbon separator in the cold box, the heavy hydricarbon is separated and then adsorbed by scrubbing solution. After that, it goes out from tower bottom, gets separated, and at last gets stored in the storage tank.

Main processes/methods used for natural gas liquefaction by LNG purification and liquefaction plant:

1) expansion refrigeration circulation

Nitrogen methane expansion or nitrogen double expansion with freon as pretreatment;

Mainly used for small type liquefaction plant with a capacity of 300,000 m3/day or below;

2) single mixed refrigerant circulation

It is divided into single stage throttling and multi stages throttling.

Liquefaction capacity: 300-2,000,000 m3/day

3) multi-refrigerant circulation

Mixed refrigerant circulation with propane as pretreatment; liquefaction capacity: 2,000-10,000,000 m3/day.

Multi mixed refrigerant circulation with propane as pretreatment and mixed refrigerant circulation by nitrogen expansion for supercooling; liquefaction capacity: 10,000,000 m3/day or above;

Only an elite team of experts from cryogenic, instrument and electronics fields is able to plan a perfect LNG purification and liquefaction plant project. In addition, the ability of processing and manufacturing must be supportive. Especially, the key technology and equipment, such as liquefaction cold boxes and tanks, are all necessary to fulfill the project. We are proud to have a strong design team as well as a manufacture team. With our rich experience, we are able to design, manufacture and install complete sets of natural gas liquefaction plant for different customers. We will help you to build your exclusive LNG purification and liquefaction plant, which is both reliable and energy-saving.

Achievements Table on LNG Project

| Achievements Table on LNG Project | |||

| S.N. | Description | Liquefaction process | Users |

| 1 | 100000Nm3/d nature gas liquefaction plant (main contractor) | Circulating liquefaction process bytwo-stage nitrogen expansion refrigeration | Chengdu Yonglong LNG Company Co., Ltd |

| 2 | 200000 Nm3/d nature gas liquefaction plant (main contractor) | Liquefaction process by two-stage nitrogen expansion refrigeration circulating and denitrification | Export to Poland |

| 3 | 135000 Nm3/d nature gas liquefaction plant (main contractor) | Liquefaction process by expansion refrigeration of mixed refrigerant N2-CH4 with pre-cooling | Inner Mongolia Erdos Xinsheng Fuel Gas Technical Co., Ltd. |

| 4 | 300000 Nm3/d nature gas liquefaction plant (main contractor) | Liquefaction process by expansion refrigeration of mixed refrigerant N2-CH4 with pre-cooling | Ningxia Yinchuan |

| 5 | 2400000ton/a,3400000ton/a nature gas liquefaction technical process(including research & development) | Liquefaction process by propane pre-cooling & refrigerating of mixed refrigerant | CNOOC North Pars project |

| 6 | 600000 Nm3/d nature gas liquefaction plant(main contractor) | Liquefaction process by refrigeration of mixed refrigerant | Inner Mongolia Erdos HangJinqi Xinsheng Natural Gas Co., Ltd |

| 7 | 1000000 Nm3/d nature gas liquefaction plant(main contractor) | Liquefaction process by refrigeration of mixed refrigerant | Inner Mongolia Erdos Runhe Nature Gas Comprehensive Utilization Co., Ltd |

| 8 | 600000 Nm3/d nature gas liquefaction plant(main contractor) | Liquefaction process by refrigeration of mixed refrigerant | Hangjinqi Hengdong Nature Gas Co.,Ltd |

| 9 | 1000000 Nm3/d nature gas liquefaction plant EPC (general contracting) | Liquefaction process by refrigeration of mixed refrigerant | Hebei Zhangjiakou State Reserve LNG Limited |

| 10 | 2000000 Nm3/d nature gas liquefaction plant EPC (general contracting) | Liquefaction process by refrigeration of mixed refrigerant | CNOOC Shanxi Weinan Nature Gas Co., Ltd |

| 11 | 270000Nm3/d nature gas liquefaction plant (main contractor) | Liquefaction process by refrigeration of mixed refrigerant | Inner Mongolia Guoneng Nature Gas Company Limited by Shares |

| 12 | 2000000Nm3/d nature gas liquefaction plant(main contractor) | Liquefaction process by refrigeration of mixed refrigerant | Inner Mongolia Xingsheng Nature Gas Co., Ltd |

| 13 | 270000Nm3/d differential -pressure type partial liquefaction LNG plant (main contractor) | Partial liquefaction process with differential pressure type | Wuhan Zhongneng Fuel Gas Limited Company. |

| 14 | 500000Nm3/d nature gas liquefaction plant (main contractor) | Liquefaction process by refrigeration of mixed refrigerant | Jiangyin Tianhe Chemical Limited |

| 15 | 1000000Nm3/d nature gas liquefaction process package | Liquefaction process by refrigeration of mixed refrigerant | Shanxin Yanchang Petroleum Group |

| 16 | 500000Nm3/d nature gas liquefaction plant (main contractor) | Liquefaction process by refrigeration of mixed refrigerant | Ningxia Yanchi |

| 17 | 1000000Nm3/d nature gas liquefaction plant (main contractor) | Liquefaction process by refrigeration of mixed refrigerant | Shanxi Qingjian |

| 18 | 20000Nm3/h LNG project with high methane gas liquefaction plant by intensive processing of resolution gas | Liquefaction process by refrigeration of mixed refrigerant | HeiLongjiangShuangYashan |

| 19 | 33000Nm3/h LNG project by methanation of coke oven gas | Liquefaction process by refrigeration of mixed refrigerant | Henan Anyang |

| No | Date | Projects | Capacity (Nm3/d) |

| 1 | 2004 | Fushan liquefied natural gas (LNG) plant in Hainan Province | 25×104 |

| 2 | 2005 | Hainan power grid Qinglan vaporizing station of power plant | 72×104 |

| 3 | 2007 | Hainan Fushan LNG plant condensate gas processing plant | 25×104 |

| 4 | 2007 | Songzi compressive gas treatment plant in Hubei province | 5×104 |

| 5 | 2008 | High energy liquefied coal bed methane project in Shanxi province | 30×104 |

| 6 | 2009 | China natural gas corporation limited Dengkou LNG plant | 30×104 |

| 7 | 2010 | Borui Lunnan LNG plant in Xinjiang province | 30×104 |

| 8 | 2011 | Heibei Cangzhou gas transmission pipeline project | 60×104 |

| 9 | 2011 | Daqing primary CNG filling station | 30×104 |

| 10 | 2012 | Tianjin Dagang oil field Binhai new energy LNG peak shaving plant | 30×104 |

| 11 | 2012 | Jiangxia 30×104 Nm3/d LNG plant | 30×104 |

| 12 | 2013 | Yibing Light Hydrocarbon technological upgrading project | 30×104 |

| 13 | 2013 | Zhaoqing CPC natural gas company LNG plant | 60×104 |

| 14 | 2006 | China Petroleum natural gas treatment plant to take off the hydrocarbon technology renovation project | 50×104 |

| 15 | 2008 | Shanxi energy CBM liquefaction project put into production, operation and management | 30×104 |

| 16 | 2010 | China natural gas corporation limited dengkou LNG production startup and operation project | 30×104 |

| 17 | 2011 | Xinjiang Borui LNG production, startup and operation project | 30×104 |

| 18 | 2011 | China natural gas corporation limited Ansai LNG project put into production, startup and operation project driving | 200×104 |

| 19 | 2012 | China natural gas corporation limited Bazhou LNG project | 100×104 |

| 20 | 2013 | Shandong taian 600000 tons/year LNG equipment localization project | 260×104 |